I haven't done anything for a while, so to get going again with glazes I dipped some of the spoons I've been making recently into existing glazes and mixed two versions of a new one - Val's Turquoise.

This time I bisque fired the spoons only to cone 04 - 1046ish as I read somewhere that they take the glaze better. Older bisque went to cone 05 or higher 1080C.

Remixed all old Cone 6 glazes lots and checked Specific Gravity.

Recorded the Spec Grav in Glaze book.

Arrowmont Blue Green ran badly and crazed a lot when it came out of the kiln. Pinged a lot. Good in bowl but crazed.

Fix this somehow? My version very glossy compared to online.

VC Matte yellow ran too. Good in bowl. Didn't craze.

Maybe they both need to be deflocculated?

Ashleys best was good. Very thick for spoons though prefer translucent.

I wrote out the recipe each time without Eckalite but I'm sure it must have gone in because the glaze worked?

Selsor Chun was great. Use again. See that some people add copper carb to bring up the blue. Test?

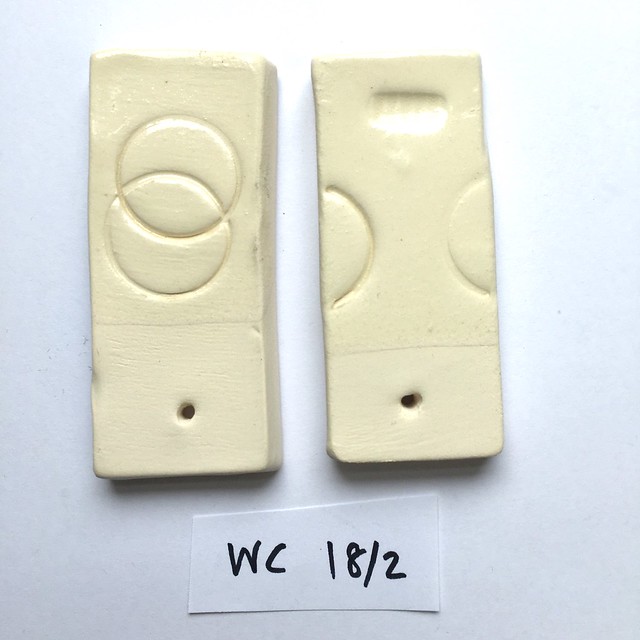

Val's Turquoise was well behaved. The lighter colour is better but could still be lighter. Its a bit flat.