Monday, 26 September 2016

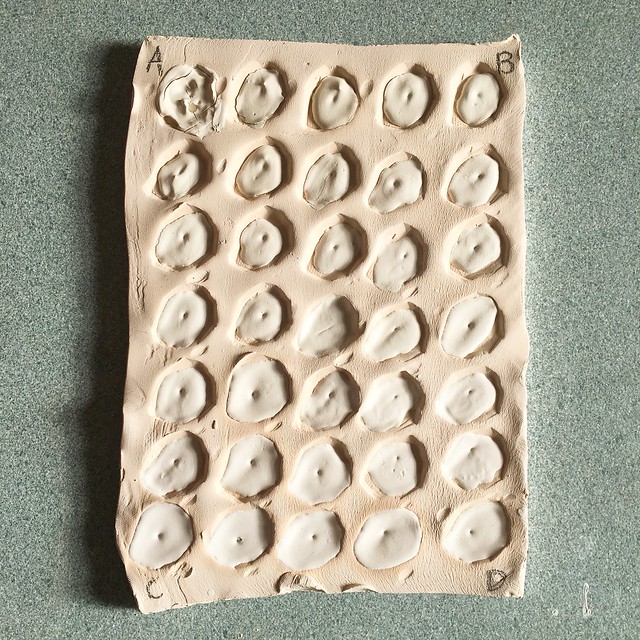

Currie Grid

Learning to do a stoneware test grid using Ian Currie's method for testing fluxes, alumina and silica ratios.

This is a Cone 6 Base Glaze.

Calculation page here.

Work out the flux ratios you want to use and then add them at the top. Click calculate and you have your formula. The Horizontal scale moves from C in the bottom left corner right towards high silica and upwards on the vertical plane towards high alumina.

Fluxes used are Frit 4124, Potash feldspar and Whiting.

Lucy Burley's Matte

I found this recipe on Ceramic Arts Daily's article about Green, Blue and Turquoise glazes. I love these colours and I'm looking for matte glazes for cone 04 firings.

I have substituted Strontium carbonate for Barium carbonate.

I did a rough line blend, rough because I started the test using a teaspoon to measure units in the blend and ran out of glaze mix.

Lucy Burley's Matte Glaze Recipe

10 Strontium carbonate

45 Frit 3134

15 Potash Feldspar

15 Ball Clay FX

15 Eckalite 2

Results

I love the colours in these tests. You can't see in the photo but this glaze bubbled at the edges.

I think this is because I didn't add enough water to the glaze mix and it went on very thick.

It isn't very matte either, a little shiny for a matte glaze. I might try to tweak it if I make it again to tone down the shininess and fix the bubbling.

Labels:

cone 04

,

earthenware

,

glaze test

,

LBmatte

Saturday, 17 September 2016

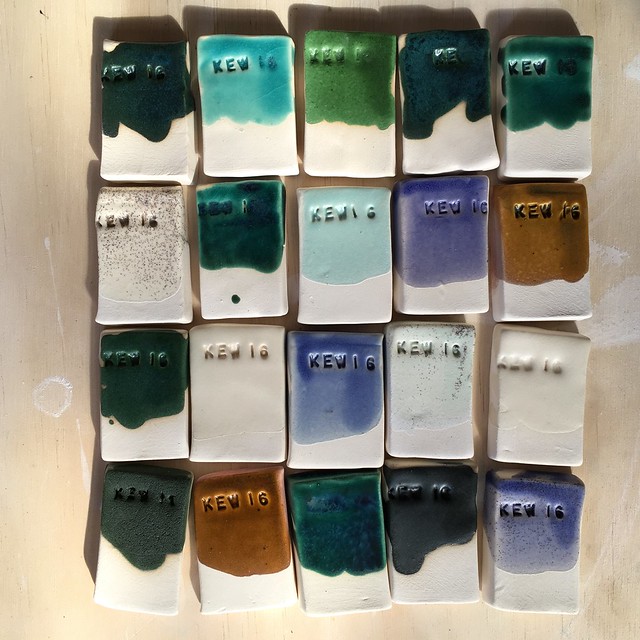

Julie's Satin Triaxial - Blog Ceramique

It's based on a cone 04 satin/matte base glaze recipe, which I think is based on the

popular Jackie's Base glaze found around the net - the ingredients are similar - but this has added Calcium Carbonate (as an opacifier?) and different ratios. I used it on Keane's Earthenware 37 fired in my home kiln, an old Ward.

I mixed this one at home and fired it with a mixed firing of bisque and glazed pieces. One of the benefits of firing to cone 04 is being able to mix loads.

I had problems with reaching temperature as I had the controller programmed wrong and the kiln turned off too early before the cone had bent. Took another hour of fiddling with the controller to get it melted.

I don't think I did slow cool on this firing but it sort of had a soak due to the mistake.

The only substitution is Eckalite 2 for EPK which is unavailable here.

While I had the base mixed I did some extra experiments with cobalt, light blue stain and rutile.

Julie's Satin Base

17 Calcium carbonate

27 Gerstley borate

7 Lithium carbonate

4 Nepheline syenite

11 Eckalite 2 (my substitute for EPK)

34 Silica

In the Triaxial

A was the base glaze,

B was 3.5% Copper carbonate

C was 1% Chrome Oxide

Results

I think I might have made the colour too strong too, I can't remember if I divided the amounts into thirds or just put the whole amount in each corner.

As it is the chrome seems unmelted and has taken on a rough burnt looking texture where it is most concentrated. The colours certainly look different to the sample tests on the BC blog.

Also the glaze has crazed in its base form and on some of the copper side.

I love the finish of this one though and will try to reformulate it to fix the crazing. Has a lovely thick buttery matte texture.

I mixed this one at home and fired it with a mixed firing of bisque and glazed pieces. One of the benefits of firing to cone 04 is being able to mix loads.

I had problems with reaching temperature as I had the controller programmed wrong and the kiln turned off too early before the cone had bent. Took another hour of fiddling with the controller to get it melted.

I don't think I did slow cool on this firing but it sort of had a soak due to the mistake.

The only substitution is Eckalite 2 for EPK which is unavailable here.

While I had the base mixed I did some extra experiments with cobalt, light blue stain and rutile.

Julie's Satin Base

17 Calcium carbonate

27 Gerstley borate

7 Lithium carbonate

4 Nepheline syenite

11 Eckalite 2 (my substitute for EPK)

34 Silica

In the Triaxial

A was the base glaze,

B was 3.5% Copper carbonate

C was 1% Chrome Oxide

Results

I think I might have made the colour too strong too, I can't remember if I divided the amounts into thirds or just put the whole amount in each corner.

As it is the chrome seems unmelted and has taken on a rough burnt looking texture where it is most concentrated. The colours certainly look different to the sample tests on the BC blog.

Also the glaze has crazed in its base form and on some of the copper side.

I love the finish of this one though and will try to reformulate it to fix the crazing. Has a lovely thick buttery matte texture.

Labels:

cone 04

,

earthenware

,

glaze test

,

test tiles

,

triaxial

Naragon White cone 6 results

Naragon White version 1

31% Soda Feldspar

2 Bentonite

Mixed dry and then water added. Divided into three pots of 66.6ml each.

The triaxial with three corners as follows starting from the apex:

A 10% Tin Oxide (100 x 10 x 33.3/100) added 3.33g

B 7% Copper Carbonate (100 x 7 x 33.3/100) added 2.33g

C 2% Cobalt Carbonate, 10% (100 x 10 x 33.3/100) added 0.66g

10% Rutile flour (100 x 10 x 33.3/100) added 3.33g

Fired to cone 6 in my Ward kiln. Slow cooled.

Results

Colour needs mixing with a blender, appears a bit grainy. Base glaze is pinkish from tin oxide. Poured rather than dipped. Need to repeat this test but concentrating on the lighter oxides, tiles 1, 2 and 3.

I like the way the rutile has added texture especially to the Cobalt corner.

Labels:

cone 6

,

glaze test

,

keanes stoneware 7

,

results

,

stoneware

,

test tiles

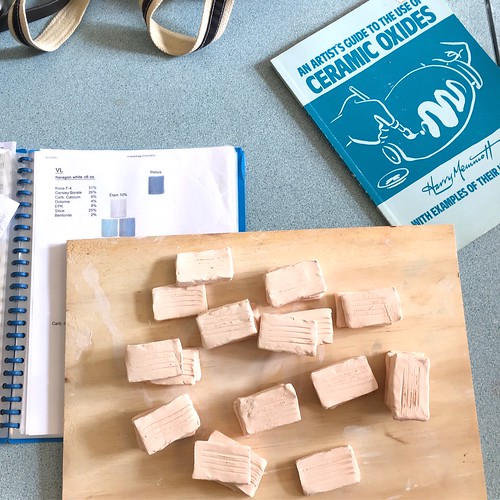

My first glaze test

My first attempt at mixing a glaze recipe from raw materials. I really love the images on the Blog Ceramique site and optimistically chose one of their Triaxial blends for my first glaze test. The base glaze recipe from Blog Ceramique is:

31 Kona F4

26 Gerstley Borate

6 Calcium carbonate

4 Dolomite

25 Silica

8 EPK

2 Bentonite

My translation substituted with Australian ingredients was this:

31 Soda Feldspar

26 Frit 3134

6 Calcium carbonate

4 Dolomite

25 Silica

8 Eckalite

2 Bentonite

Mixed dry and then water added. Divided into three pots of 66.6ml each.

The triaxial with three corners as follows starting from the apex:

A 10% Tin Oxide (100 x 10 x 33.3/100) added 3.33g

B 7% Copper Carbonate (100 x 7 x 33.3/100) added 2.33g

C 2% Cobalt Carbonate, 10% (100 x 10 x 33.3/100) added 0.66g

10% Rutile flour (100 x 10 x 33.3/100) added 3.33g

Labels:

cone 6

,

glaze test

,

stoneware

,

triaxial

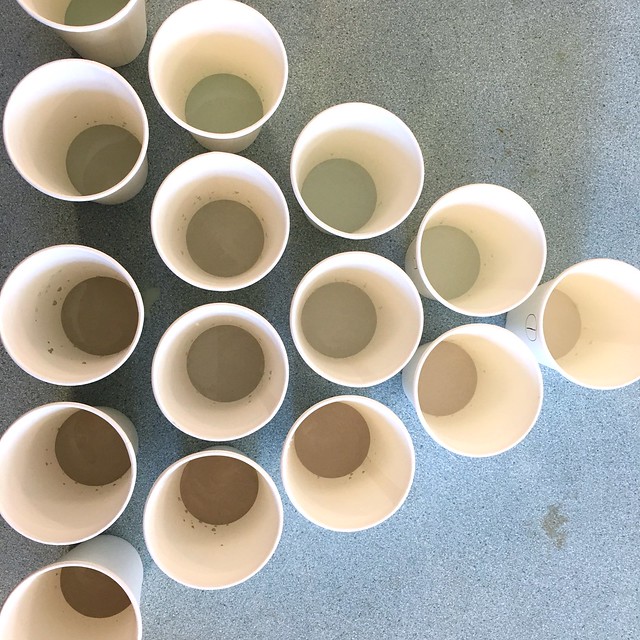

pine street glaze course

I'd been interested in glaze making for a while when I enrolled in Pine Street's glaze making course in August 2016. The teacher was Greg Crowe.

In the first week we chose a glaze test to suit the type of firing we were doing. I've been wanting to experiment with stoneware clay fired to cone 6 after seeing so many great glazes and recipes online. Until now I've been focussed on earthenware, which I still like for its great colours, so I think I'll work to find recipes for cone 04 too.

I wasn't sure my kiln could fire to cone 6 temps but a test firing this week shows it easily makes that mark. Early on in this ceramics journey I bought a wheel and a kiln because I want to make and fire everything inhouse, it means I can work at my own pace and control each part of the process. My little old Ward kiln with its new controller is working well and I am slowly refining my firing schedules to get the perfect rise and fall. To mix up my own glazes is a logical progression.

My reading list is up in a link list there on the left. I'll keep adding to it as I go and would love suggestions. If you know of any good glaze references or have your own glaze/ceramics blog leave the link in a comment below.

Week one at glaze school we made test tiles for future firings in a number of ways, both flat and pinched and napkin ring style and left them in the kiln room for firing to use for our first test next week.

Friday, 16 September 2016

glaze testing blog

This is a new blog to record my glaze testing. Please see my regular blog www.flowerpress.blogspot.com for everything else. I think one of the most important thing for glaze testing will be good record keeping so I hope to keep up with recipes, outcomes and photos here. I am focussing on Earthenware cone 04 recipes and Stoneware cone 6 firing recipes. The two clays I've been using at the moment are Keanes White Earthenware 37 and Keanes Stoneware 7.

Subscribe to:

Comments

(

Atom

)