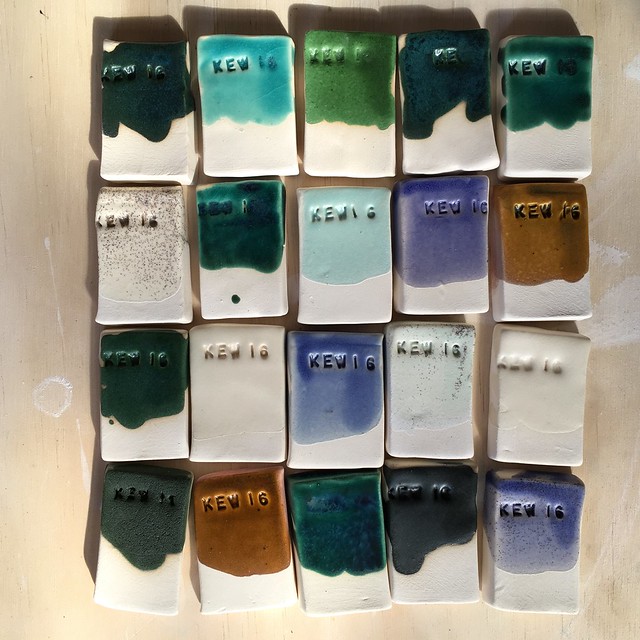

Testing of five different Cone 04 matte or satin base recipes. All of the recipes have very similar ingredients, but different ratios.

These tests weren't ultimately successful as a week later four of them had crazed.

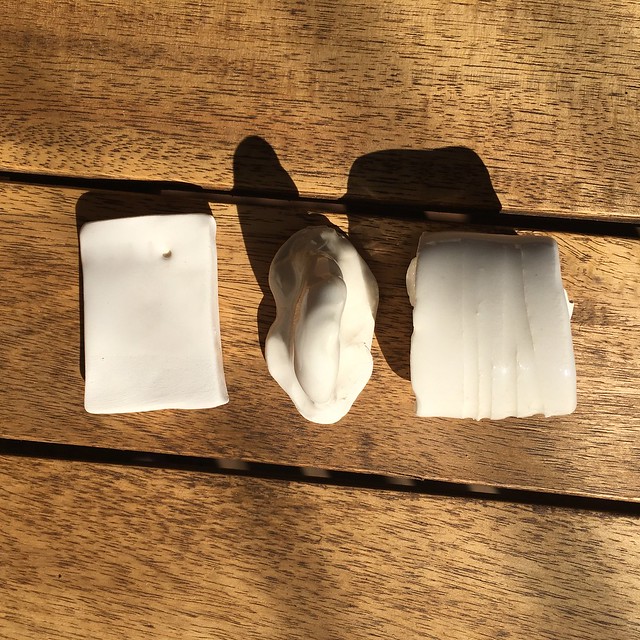

Retesting Julie's Satin (JMBC) and also testing a variation (JMBC revA), revised using hints from Glaze Simulator.

A. Jackie's Matte via Priscilla Hollingsworth

38 Gerstley borate

10 Lithium carbonate

5 Nepheline syenite

5 Eckalite 2

42 Silica

5% Zircosil

B. Satin Base (from here)

65.5 Ferro frit (4124) 3124

11 Nepheline syenite

5 Eckalite

42 Silica

C. Julie's Satin (from here)

27 Gerstley borate

7 Lithium carbonate

17 Whiting

4 Nepheline syenite

11 Eckalite 2

34 Silica

D. Hirsh's Satin Matte

32 Gerstley borate

9 Lithium carbonate

17 Whiting

4 Nepheline Syenite

4 Eckalite 2

35 Silica

2% Bentonite

E. Julie's Matte revised to fix crazing (JM rev A)

27 Gerstley borate

6 Lithium carbonate

17 Whiting

4 Nepheline syenite

12 Eckalite 2

34 Silica